Credit:

Reviewed / Timothy Renzi

Credit:

Reviewed / Timothy Renzi

Recommendations are independently chosen by Reviewed's editors. Purchases made through the links below may earn us and our publishing partners a commission. Prices were accurate at the time this article was published but may change over time.

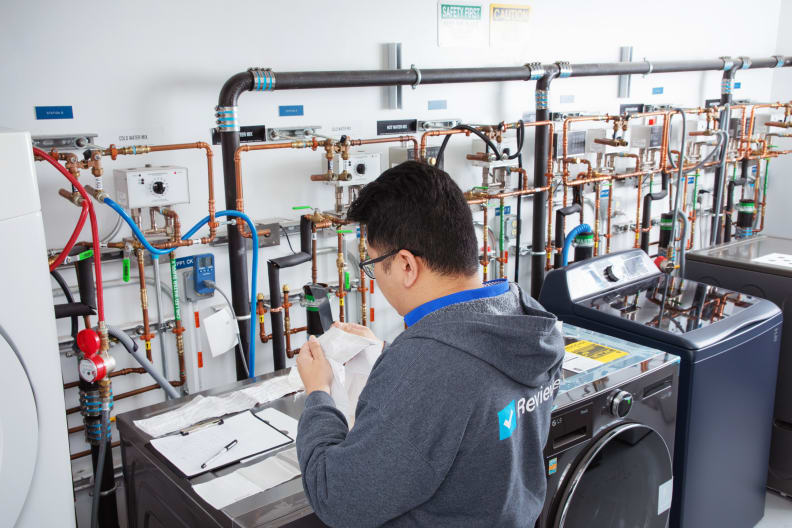

For over a decade, the Reviewed lab team has been testing large appliances—from fridges to dishwashers to washers and dryers. In total, we've spent over 12,000 hours testing every type of appliance you can buy for your home.

We control everything about the testing process, from the temperature and quality of the water to the detergent and even the stains.

When it comes to washers, we've reviewed models from just about every popular brand—Maytag, LG, Electrolux, Samsung, GE, and Whirlpool, among them—and in every style—front-load, top-load, laundry centers and combo units.

When we get a washing machine into our labs for testing, we put it through the same rigorous, standardized testing process that we run every washer through. We've developed this battery of tests ourselves, based on industry standards, customer research, and years of hands-on experience.

Our testing is overseen by Reviewed's chief scientist, David Ellerby, PhD, and focuses on balancing stain-scrubbing strength against the wear-and-tear damage that excessive mechanical action will have on your clothes.

According to Ellerby, "In theory, it's easy to clean clothes: You churn them around in hot water and chemicals until the dirt falls off. In practice, this would destroy most fabrics. That's why we focus our testing on stain removal and fabric wear for each wash cycle. In the lab, we're looking for washing machines that hit the sweet spot where high-performance cleaning doesn't hurt your clothes."

Here is an overview of how we test washers in the Reviewed labs, and why we run the tests we do.

Standardized stains make for consistent testing

Above you can see several standardized AHAM stain strips. The one in the middle is before washing, while the faded strips on the top and bottom have both been through a wash cycle.

In order to test how a washer cleans clothes, we first need some dirty clothes—or at least some common stains. This is where the AHAM stain strips come in. AHAM stands for Association of Home Appliance Manufacturers, and their testing standards provide consistency across appliance manufacturers and reviewers, like us.

These standardized strips have swatches for sweat, oil, cocoa, blood, and red wine. What we do is carefully measure each swatch with a spectroscope, which lets us know its exact color value.

We attach the stain strip to one of the items in an AHAM-standard load of laundry, which consists of towels, pillowcases, and sheets. We then fill up the machine using our standardized laundry detergent and run a wash cycle.

When the cycle completes, we measure the swatches with a spectroscope again, to find their post-wash color values. Using the control swatch as our baseline, we can then determine exactly how much of each stain was washed away during a cycle.

This spectroscope helps us measure exactly how stained something is, both before and after a wash cycle, which lets us determine exactly how much of the stain was washed away.

As Jonathan Chan, our manager of lab operations points out, "Our testing is designed to control for as many variables as possible to zero in on the washer's performance. We control for water temperature and hardness, always use the same formula of detergent, the same type and amount of laundry, and mechanically replicated stains. So when we say one washer is better than another, they ran the same exact race."

Effective spin cycles can save your dryer

A spin cycle can remove water from clothes significantly faster and with less energy than your dryer.

Scrubbing out stains isn't the only thing your washer does. When it's done sloshing your laundry around it then has to remove as much water as possible in the spin cycle.

Spin cycles work by leveraging the power of spinning really fast, causing centrifugal force to extract excess water from your clothes. The higher the spin speed, the more water gets removed. We measure this by weighing the load after the spin cycle is complete.

The spin cycle is important because it removes pounds of water from your clothes for relatively low energy investment. One of the most energy-expensive things you can do is heat something up, which is how your dryer goes about removing water from laundry.

A good spin cycle can save your dryer some significant work, letting it operate longer before a replacement is needed. It's also just safer on your clothes, and results in less wear-and-tear damage because it doesn't use heat.

We look for wear-and-tear

These mechanical action strips help us see exactly how rough a washer or dryer will be on your clothes.

The key ways a washer gets rid of stains are through chemical action, mechanical action, and heat. All three of these can also contribute to wear-and-tear damage on your laundry, but especially mechanical action.

To test how much force your laundry gets put through, we use mechanical action strips. These strips are small squares of fabric with five holes punched out of them. They look similar to the five side of a standard die.

How these strips work is we first attach them to a towel or sheet in the standard load, making sure that the punched holes are clean with no visible loose threads. After a cycle, the edges of the fabric will be frayed and threads will be pulled away from the main body of the fabric.

A very patient lab technician then hand-counts each and every thread pulled loose in this way—the more threads pulled loose, the harsher the mechanical action involved.

We keep tabs on the washer's overall efficiency

Thanks to our elaborate testing setup, we're also able to monitor exactly how much water and energy each washer is using to complete a wash cycle.

By knowing the amount of water and electricity going into the washer, coupled with how clean the washer is able to get a load of laundry, we can then determine how efficient the washer is. If a washer is able to offer the same quality of clean and uses less water and electricity, it scores higher than units that are less thrifty with their resources.

We also use the washer just like you would

When using a washer, we pay attention to any friction its design causes in the user experience, be it from loading, unloading, or punching in your next wash cycle.

An important part of testing any appliance is actually using the darn thing. A washer might have impeccable cleaning power, but if the controls are unresponsive or confusing, or the machine itself is just awkward to load, that can significantly dampen how the machine feels to use.

As such, we make sure to get in and use each washer just as we'd use them in the real world. We load and unload laundry, we program in cycles, we open and close the door a few dozen times. We make sure to get a feel for the machine and what it takes to operate it correctly.

We're always updating our testing as washer technology evolves

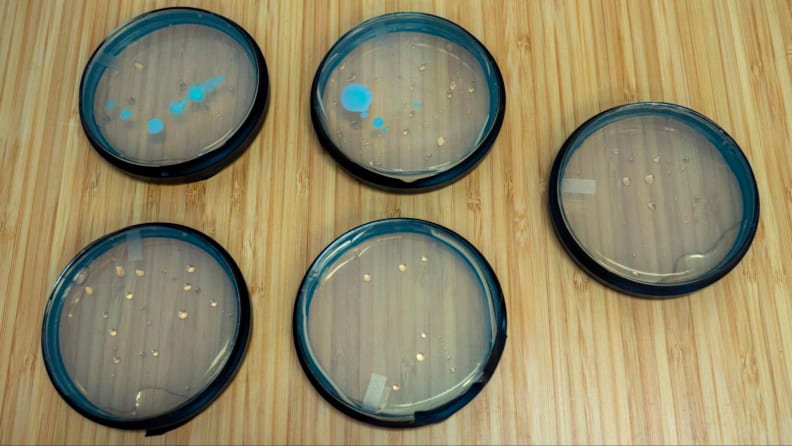

When washers started adding anti-microbial coating to various surfaces, we started breaking out the petri dishes.

Just because we're confident in our current battery of tests doesn't mean we aren't also always improving. As new features start making their way into washing machines, we develop new testing in tandem to make sure those features do exactly what manufacturers promise they're going to do.

One of the newer tests we're developing is a method of testing antimicrobial surfaces. GE in particular has been incorporating Microban antimicrobial coating into various frequently-touched surfaces across their appliances.

To know how effective that coating was, we took cultures from various areas around the washer, including the antimicrobial surfaces, to see how effective the coating was at preventing the spread of germs—as you can see from the clarity of the two lower slides, it was effective!

Whether its new coatings, new fixtures, or new functionality, we'll make sure we're there with the latest and greatest means of testing whether or not these features are worthwhile or a waste of your money.